Winters can be harsh and wreak havoc on oil and gas extraction systems. It’s essential for plant operators to properly winterize their assets against extreme temperatures to prevent product viscosity and keep their resources moving.

Many oil and gas plants have a winterization plan in place for the different parts of their systems. However, these plans typically involve several companies taking care of the various aspects of the system. This approach results in a winterization strategy that is often disjointed and lacking synergy between the different electrical, insulation, rope access, and scaffolding contractors.

When scopes are segregated in this manner, the results can add up to increased costs, lost productivity, and no accountability. Communications can easily break down, and coordinating tasks between the contractors can be a frustrating waste of time and resources. Worst of all, there is also an elevated risk of fluid viscosity, crystallization, or condensation – a situation that can cost you thousands in avoidable production downtime and repair costs.

Your system needs to operate as a seamless whole to maximize efficiency all year round. Therefore, your winterization program needs to perform as one holistic solution to ensure that your system is protected against deep freeze, keep production moving, and extend the lifespan of your equipment.

Read More: What Is A Heat Management Solution?

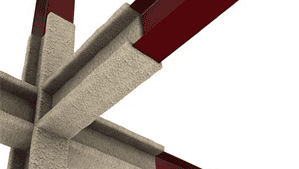

The solution is a prioritized maintenance program for insulation and electric heat trace (EHT) that streamlines processes, improves efficiencies, and reduces costs without sacrificing project quality or system performance.

MSCP offers a Heat Management Winterization Program that integrates the entire winterization process for complete cold-weather protection available for your entire system.

One of the most critical aspects of our solution is an in-house team of Heat Management Specialists (Heat trace, Insulation, and rope access). Our sole-source approach toward a heat management winterization program saves time and money from having to communicate with several different contracting companies.

We also provide our unique digital work packages, which contain crisp, clear photos taken in the field that visually document the work our field specialists complete that day. New digital work packages are created daily and are always available for your inspection and review.

When you hire MSCP’s team of experts to design, develop, and implement a customized winterization solution, you reap these tangible benefits as soon as we start the project:

- Increased Productivity: Progress is made faster with fewer delays, making managing the entire process easier.

- Complete Visibility: Real-time visibility into project status and goal tracking is easier than ever before through MSCP’s digital work packages

- Reduction In Scaffolding: MSCP’s winterization clients have seen up to 90 percent of scaffold work eliminated without affecting the quality of the work

- Significant Cost Savings: Clients see a decrease in their overall spending while accomplishing more in less time

- Stop Juggling Multiple Contractors: Just a single phone call to MSCP is all that’s required to address any concerns about your heat trace winterization or start a new project, eliminating the need to work with multiple contracts, invoices, and communications

- Fast Access To Heat Trace And Insulation Materials: MSCP is the only company that offers heat management materials along with the engineering and technical services to design, create, audit, maintain, and commission your heat management system

- The Entire Project Is Fully Managed: MSCP takes charge of all project management and coordination so you can focus on other areas of your business

- Rigorous Safety Standards: All work carried out by the MSCP team is subject to strict safety protocols, bringing you peace of mind that we’re committed to workplace safety as much as you are

You get more than just a project quote when hiring MSCP to design and implement a Heat Management Winterization Program. We take the time to learn all about your system and ensure we get a complete look at how everything works together. We then provide you with a list of comprehensive recommendations that will solve your current heat trace and insulation issues and protect your system down the road.

Our secret to accomplishing an all-encompassing, future-proof solution is employing our unique and innovative take on the Theory of Constraints methodology, which identifies bottlenecks in the system and leverages them to make significant process improvements. We go this extra mile to help you save money on long-term maintenance and repair costs.

The goal at MSCP is to help your facility achieve zero downtime due to heat management issues with a cost-effective winterization solution that eliminates the worry of freezing temperatures affecting production. Contact us anytime to learn more about how we can help you.