About MSCP

At MSCP, we thought long and hard to analyze the major problems affecting the sector we serve. We realized that fragmentation within and among suppliers led to increased cost, effort and suboptimal performance. It did nothing to cope with an ever tighter network of interdependencies and the complexity this generates. We saw that in a fast-evolving scenario, clients need to focus increasingly on operational excellence to accelerate the flow of materials while being mindful of environmental and social impact.

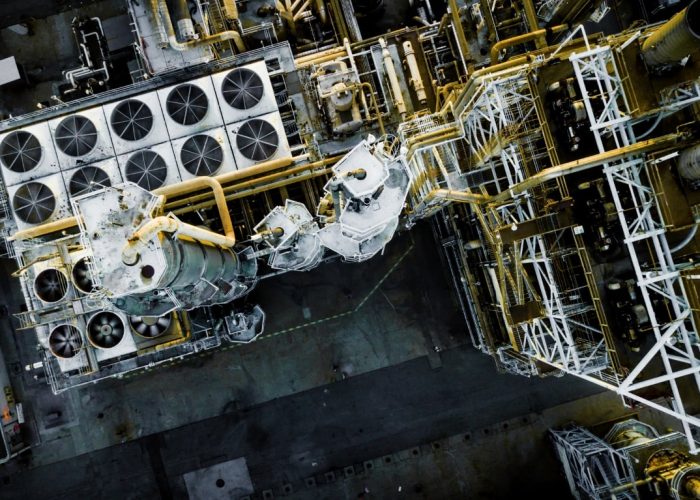

We were conscious that we were part of the problem of a much bigger value network and that something in our way of operating had to change. Focusing on the individual components of our offer was not enough to produce the outcome stakeholders were seeking. To overcome this and step up to a new level of performance that could manage complexity, we decided to adopt a systemic approach to how we think and operate. This is how we developed our breakthrough solution of Heat Management as a System and built the infrastructure to be able to deliver it.

Our state-of-the-art distribution method is unrivalled in supplying materials as and when needed in a reliable way. Our advanced manufacturing method ensures shorter lead times and reliable and timely production of our quality materials.

Continuous improvement is not sufficient. In a fast-changing world, we must also continuously innovate. We work constantly to identify areas where we can add value by relentlessly challenging our assumptions about the way we operate and interact to develop true innovations.

MSCP is evolving and expanding as an organization and continuous learning is a necessity. Our school and training programs provide the learning path for our people from five continents to develop their competencies and expand their horizons as we grow throughout our journey from contractor to strategic partner.

Chris Maki, CEO, MSCP Heat Management Solutions

North America’s leading heat trace and insulation product and service providers since 2011

The MSCP Difference

Our services encompass electrical heat tracing, insulation, control panel assembly, and rope access – all available in-house. Moreover, we supply all the materials required for the initial build, installation, repair and maintenance.

This eliminates the need for clients to shuffle multiple contracts, contractors, invoices, and communications.

MSCP is the only company that offers heat management materials along with the engineering and technical services to design, create, audit, maintain, and commission your heat management system.

MSCP’s Beginnings

In our first project, we tackled the transformation of heat management systems in the Alberta oil sands. This involved addressing challenges by seasonal temperature fluctuations that impact the continuous flow of natural resources. Our team responded by developing a documented, repeatable program aimed at mitigating operational disruptions caused by subpar insulation installations and heat tracing failures. Notably, this program has proven highly successful across various SAGD and upgrading facilities, with capacities ranging from 40,000 to 200,000 bpd. Despite being a young company, we were already making a significant impact—signaling the beginning of our journey.

Our Management Method

Our methodology is informed and inspired by The Decalogue*, a cohesive integration of the teachings of Dr. Deming on Quality and the Theory of Constraints (TOC).

We look at our organization as a system, i.e. a network of interdependent components aimed at a well understood common goal. Our focus is on Quality, the management of the variation that affects all our processes, and a strategically chosen leverage point that we call constraint, where we generate the maximum value for our client. Systemic measurements are in place to monitor and improve the performance of our system as a whole.

Clarity on the inputs and outputs of processes ensures that people are involved and engaged in meaningful interactions. This inherently prevents silos and accelerates the flow of communication, information, and delivery of services and materials.

Applying a constraint-based approach to the flow of our manufactured products ensures shorter lead times and reliable and timely production of quality materials. Also, we manage our supply chain with a method based on replenishment and we apply process behaviour charts to supply materials as and when needed in a predictable and reliable way.

We use a systemic, finite capacity approach to schedule and manage competencies in our projects. Process behavior charts are used to measure project buffer consumption, providing real time visibility on the progress of projects and the variation affecting task execution. It allows us to intervene in a timely manner to ensure project completion is on time and within budget. Moreover, scheduling competencies gives us the flexibility to operate as a network of projects with no resource contention.

Our management approach is further enhanced by a systems thinking method for problem solving that supports us in challenging limiting beliefs and aids our ability to continuously innovate our products and services.

We believe it is important that our clients have an understanding of how we operate and why, as they are an integrated piece of the offering we provide. Through true partnership with our clients, we can implement solutions that concretely improve day to day operations, identify continuous improvements and allow them to focus on what they are world class at, rather than trying to manage something that is tertiary to their business.

*The Decalogue management method was first introduced in the book ‘Deming and Goldratt: The Decalogue’ by Domenico Lepore and Oded Cohen, North River Press, 1999.

Innovative Product Development

Our hands-on field experience gave us insight into how our clients can get the best results for their heat management investment. We recognize their need for reduced material costs, shorter MI cable lead times, and engineering services with the lowest overall ownership cost. With these needs firmly in mind, we developed a full heat trace product line that includes mineral insulated cables, self-regulating cables, junction boxes and accessories.

We tailored our engineering services to implement these new innovative products, allowing us to provide a faster turnaround on systems design.

MSCP is committed to ongoing transformation that provides our clients with the most innovative heat management on the market today and into the future.

Investing in People

MSCP is a Canadian company that takes pride in investing not only in our people but also in our nation. We are committed to setting an example by mentoring the next generation of skilled electricians, insulators, and engineers. Our goal is to foster a workplace culture that encourages professional growth, rewards commitment, and promotes equality for every member of our expanding team.

You can always count on honesty, courtesy, and respect when interacting with a MSCP team member. We wouldn’t have it any other way.

Quality Products

Case Studies

HMS School

Our Leadership Team

Chris Maki

CEO

A true industry visionary, Chris leads the heat management industry revolution by building a progressive organization focused on continuous learning and development. He has combined the fragmented pieces of insulation and heat trace materials and services into a new industry standard called heat management. Chris continuously improves our products and services to ensure our clients don’t worry about their processes freezing or setting up again.

Rafael Arruebarrena

Director of Operations

Ensuring low variation across company operations, Rafael champions the adoption of standard processes and procedures, oversees successful project performance, and guides project managers in applying our Theory of Constraints and profound knowledge to the business.

Jonathan Chimuk

Director of Projects

Jonathan is a versatile and innovative problem solver passionate about building cross-functional project teams dedicated to the customer experience. He’s recognized as a service-focused leader driven to push engagement, performance and productivity while maintaining culture and MSCP’s entrepreneurial vision to transform the heat management industry.

Derek Fraser

Operations Manager, Ontario Operations

Derek provides an inspired leadership for the organization. He promotes a company culture that encourages top performance and high morale. He builds alliances and partnerships with clients and employees and formulates strategic operational objectives.